Privately-held Cooksville Grain Co. handles only two crops at its single location in Cooksville, IL – corn and soybeans.

Privately-held Cooksville Grain Co. handles only two crops at its single location in Cooksville, IL – corn and soybeans.

But when those crops are harvested at the same time in the fall and both are being delivered to the elevator simultaneously, that can create a bottleneck and cause its busy patrons to wait in lengthy truck lines.

“When some trucks had corn and some had soybeans, we were having to make sure we were cleaning out the receiving pits completely from one commodity, before we began receiving the next one,” says General Manager Lori Mott, who has been with Cooksville Grain for 13 years. (Prior to that, Mott worked as an independent grain broker.)

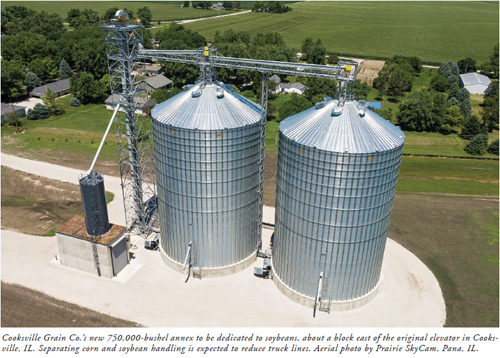

Mott has been blessed with an active board of directors, and the solution they came up with was to build a second elevator about a block east of the existing elevator. The annex is dedicated strictly to handling soybeans, while the original elevator will handle corn.

To make room for the new elevator, the board voted to purchase a 22-acre site, which Mott says will provide enough space for an eventual eight corrugated steel storage tanks. Until then, the unused land is being rented out for farming.

“It’s the Cadillac of grain elevators,” says Mott of the roughly 750,000-bushel, fully automated facility.

Cooksville Grain hired Koehl Bros., Fairbury, IL (815-692-2326), as general contractor and millwright on the project after taking bids. “Their work is very good, clean, and neat,” Mott comments. “We liked their design.”

In addition, SKS Engineers LLC, De- catur, IL (217-877-2100), did structural engineering on the project.

Automated Electric and Service LLC, Le Roy, IL (309-962-8414), supplied automation systems, including a full motor control center, automated pit and loadout, and a PLC workstation with touchscreen controls.

Construction began during the summer of 2017 and was finishing up when Grain Journal visited in late June 2018.

The Annex

Soil conditions made construction a challenge at the site. It required excavation and 26 tons of fill material, although no pilings were needed.

Koehl Bros. constructed a pair of GSI 350,000-bushel corrugated steel tanks standing 72 feet in diameter, 96 feet tall at the eaves, and 115 feet tall at the peaks.

The tanks have flat floors, outside stiffeners, 12-inch GSI X-Series ze- ro-entry sweep augers, 12-cable Rolfes@ Boone grain temperature monitoring systems, and BinMaster tilt switch level indicators.

The Decatur Aeration-designed aeration system consists of a pair of 75-hp Chicago Blower centrifugal fanspertank supplying 1/7 cfm per bushel through in-floor ducting.

Incoming trucks supply grain through a 1,200-bushel mechanical receiving pit. The pit is enclosed in a concrete structure rather than the more common steel for durability over time. The pit feeds a GSI 20,000-bph leg equipped with a single row of Tapco 20x9 vented buckets on 10-inch cen- ters, mounted on a 22-inch ContiTech belt. At the top of the leg, grain passes through an arrangement of two-way valves, which in turn, sends it out to storage via GSI 20,000-bph overhead drag conveyors.

Each tank has a pair of sidedraw spouts and also can empty onto a 5,000 bph GSI drag in an above-ground tunnel running back to the receiving leg. the valves on top also can send grain via gravity spout to a 5,000-bushel Meridian surge tank over the receiving pit for truck loading.

Ed Zdrojewski, editor

Cooksville Grain Co.

Cooksville, IL • 309-725-3214

Founded: 1906

Storage capacity: 305 million bushels at one time

Annual volume: 4 million bushels

Number of employees: 4

Crops handled: Corn, soybeans

Services: Grain handling and merchandising, forward contracts

Key personnel:

- Lori Mott, general manager

- Toni Krenkle, bookkeeper

- Randy Kemplin, operations

- Adrian Snyder, operations

Supplier List

Aeration fans: Decatur Aeration

Bin sweeps: GSI

Bucket elevators: GSI

Catwalks: GSI

Contractor: Koehl Bros.

Conveyors: GSI

Electrical contractor: Automated Electric & Service

Elevator buckets: Tapco Inc.

Engineering: SKS engineers LLC

Excavation: David Leake Excavation, Kennedy Farm Drainage, Jerrod Boyle Excavation

Grain temp system: Rolves@Boone

Leg belting: ContiTech

Level indicators: BinMaster Level Controls

Millwright: Koehl Bros.

Motion sensors: 4B Components Ltd.

Steel storage: GSI, Meridian Mfg. Inc.

Support tower: GSI

Trucking: Reynolds Express, Jesse thomas, Brad Fish, Denny Weber, Greg Leake, Terry Brown, Ron Weber Trucking