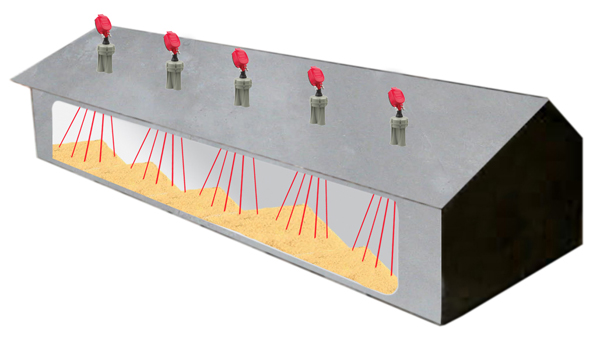

Operations challenged with managing inventory in covered storage bunkers or flat warehouses have a new option that combines leading-edge software and the 3DLevelScanner acoustic sensor to measure the level of materials piled under structures. Multiple sensors measure and map levels across the material surface, while MultiVision software separates the piled material into virtual sections. Minimum, maximum, and average levels per section are reported for up to 99 unique sections. The data is aggregated to output a visual showing the topography of the entire storage bunker.

This first-of-its-kind solution is used to estimate inventory and improve production efficiency. Identifying high and low sections allows for automating process control and managing the filling or extraction of materials through cone-shaped hoppers in the bottom of the bunker or warehouse. In proven installations, up to 20 3DLevelScanners have been mounted in the upper structure of the roof. The bunker is virtually divided into sections as small as 1.5 by 1.5 meters with the 3D sensors continuously measuring changes across the surface and providing unique visual and data reporting of inventory in the massive structure. This cutting-edge technology is ideal for copper, alumina, corn, coal, or other ores, aggregates, or grains stored in covered structures.